Product Details

Product Introduction

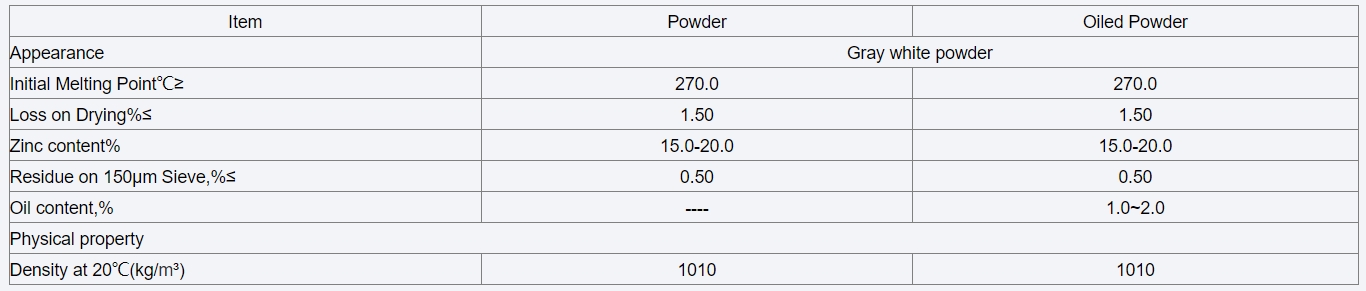

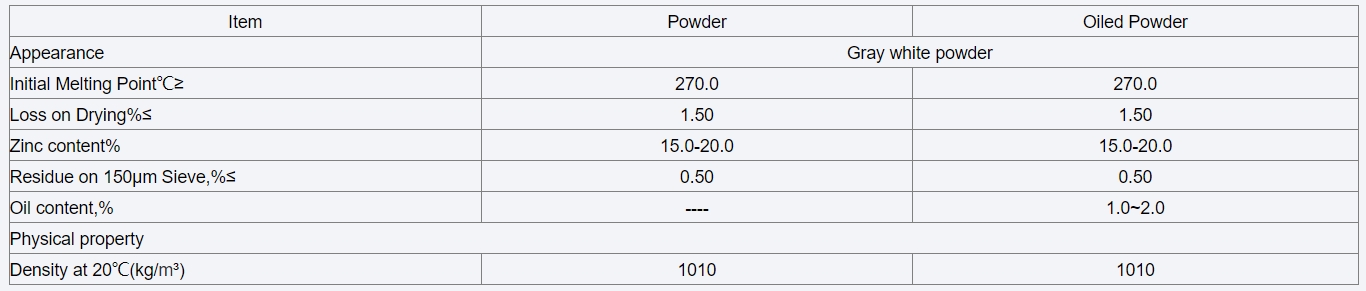

Rubber antioxidant MBZ (Zinc 2-mercapto benzimidazole, molecular formula C14H10N4S2Zn, CAS number 3030-82-6) serves as a premium rubber antioxidant primarily utilized in natural rubber (NR), chloroprene rubber (CR), ethylene propylene rubber (EPR), styrene-butadiene rubber (SBR), and nitrile rubber (NBR). Features of this product include an off-white powder form, an odorless profile with a distinctly bitter taste, solubility in acetone and alcohol, yet it remains insoluble in benzene, gasoline, and water. When it comes to thermal oxidation protection, MBZ rubber antioxidant demonstrates superior efficacy when synergistically combined with amine antioxidants. Alternatively, it can function effectively on its own or be paired with other antioxidants such as DNR or AP. Notably, its initial melting point is a minimum of 270℃, the drying loss rate does not exceed 1.50%, zinc content ranges from 15.0% to 20.0%, and the residue rate on a 150μm sieve is capped at 0.50%. The product density is recorded at 1010kg/m³ under 20℃. For packaging, it is available in 20kg plastic woven bags, plastic-paper composite bags, or kraft paper bags. Storage conditions should ensure a dry, well-ventilated area, shielded from direct sunlight, with a shelf life extending up to 24 months.

Advantages and features

1. Delivers effective thermal oxidation protection, particularly when utilized alongside amine antioxidants. 2. Features a high initial melting point (not lower than 270℃) and a low drying loss rate (not exceeding 1.50%), ensuring product stability throughout the processing stage. 3. Maintains consistent zinc content (15.0-20.0%), significantly enhancing antioxidant performance. 4. Acts as a non-polluting antioxidant, presenting an odorless yet slightly bitter profile, adhering to environmental protection standards. 5. Soluble in both acetone and alcohol for versatile application across various scenarios, while remaining insoluble in benzene, gasoline, and water.

Application Scenario

1. Applications include natural rubber (NR), chloroprene rubber (CR), ethylene propylene rubber (EPR), and various other sectors. 2. Ideal for aging resistance treatments in the rubber, plastic, and related product industries.

.jpg?x-oss-process=image/resize,m_fill,h_300,w_300/format,webp)

.jpg?x-oss-process=image/resize,m_fill,h_300,w_300/format,webp)